A grandfather asked his granddaughter where milk came from and she said, “From the shops grandpa.” Is she wrong? Well, technically not, but you know what I mean. On the other hand, it’s also not as easy and clear cut as most people think. Definitely not just a case of “Have cows, milk cows, bottle milk, sell milk”. This I learned on a recent media visit to Woodlands Dairy in Humansdorp as part of the 30 year anniversary of their founding in 1995. I thought I had an idea how it worked, but heck was I wrong.

Our visit started at Woodlands Dairy in Humansdorp on the Thursday afternoon and ended on a dairy farm Friday morning. For the sake of the natural flow of milk (did you see what I did there?), I will start this post on the farm and work my way to the dairy plant. It may feel a little back to front seeing that the post is actually about Woodlands, but well start with a jog on the farm and end with the main sprint. Natural flow and all.

We received a lot of information during the visit, with quotes from Woodlands Dairy Founder and now Executive Director Lex Gutsche, new CEO Helen McDougall, Sustainability Manager André Adendorff and a couple of other role players. These have been reported on by the Daily Maverick, Herald (here and here), Algoa FM, MyPE, Farmers’ Weekly, BizCommunity, FoodStuff SA, and a few of other publications. This is not a news site so I would rather share some of the info that I saw and picked up during the visit. Info that had me go, “WOW!”, and hopefully you will too. If my facts are a couple of liters, kilograms, degrees or whatever off, I blame my badly written notes. Also, see this as my disclaimer.

Half of us got to visit Grassridge Farm just outside Oyster Bay. They’ve been involved with Woodlands from the start and their dairy herd is split between two farms with 783 cows on Grassridge Farm and 538 on Kromhout Farm. The milk about a 1000 cows a day, TWICE, with an average production of 17 liters per cow.

An interesting bit of information they shared with us at the farm is that there were 7000 commercial dairy farmers in 1997 and by 2022 there were less than 1000 commercial farmers. It doesn’t mean dairy production has decrease though. Most farmers who have stopped farming have sold their farms to existing dairy farmers who then increased their own production through the acquisition.

Grassridge Farm has a modern rotary milking parlour which basically is a carousel ride for dairy cows. I was amazed how the cow just walked into the empty stall on her own when it comes by and how she just reverses out on her own when it comes around again.

As she steps into the stall the electronic reader reads the info microchip attached to the cow’s ear. The system knows exactly where she is in her annual milking cycle, how much milk she gives and how much food she has to receive because of that. She then gets just enough feed in her trough according to this. The chip is then read again as she leaves the palour.

The carousel doesn’t stop moving during the whole milking process. The cow steps in, and the four suckers are attached to her teats by the workers. As soon as the computer picks up that she’s giving less than a certain amount of milk per whatever seconds, the suckers let go and falls off.

Once the suckers let go, one of the farm workers put a disinfectant onto the teats and the suckers are cleaned out before being used on the next rotation again. This is also where I realised for the first time how much water is required in dairy farming. The equipment needs to be cleaned the whole time and the dairy floor needs to be washed off frequently. You can’t really tell a cow when she’s allowed to go potty and when not.

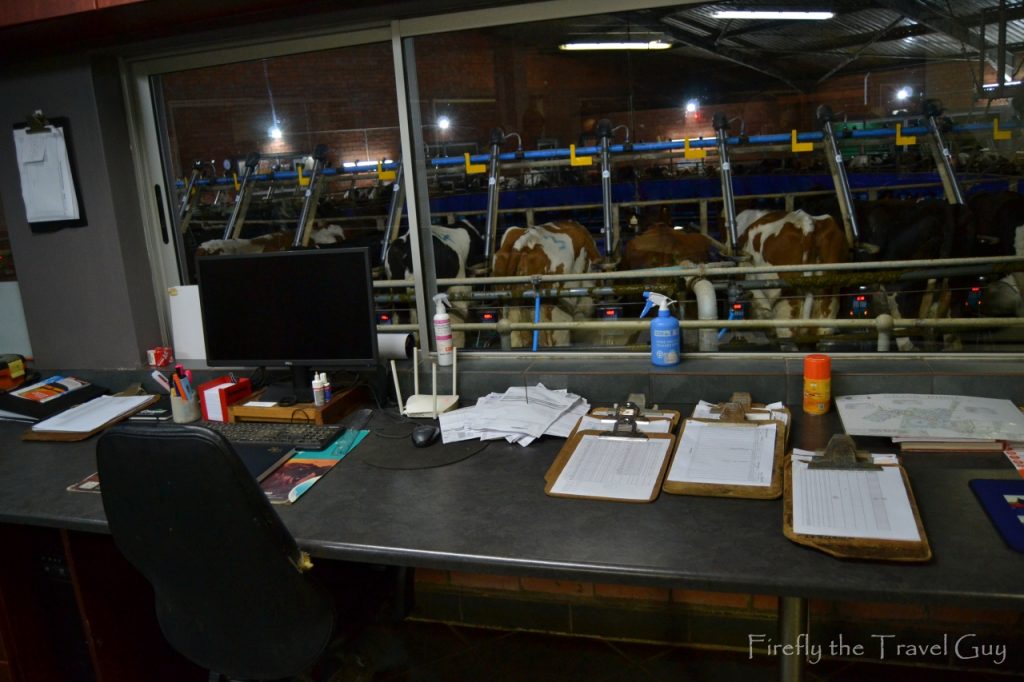

The dairy office and control room felt a little like the bridge of the Enterprise. Huge windows, high back chairs, computer screens and flashing lights. This really is a professional setup. But it’s not all about milking cows though.

In the old days the cows were probably just chased into a camp and when the grass or lucerne gets too short, they get moved to another camp. These days the camps are managed just as scientifically as the rest of the dairy process. They keep track of exactly when each camp is planted, how long it’s been growing and how tall the grass or lucerne is. They know when to move the cows into those fields and when to move them on again. Un-freakin-believable.

Woodlands has a whole fleet of dairy trucks that pick the milk up from the farms and transports it to the Woodlands Dairy Plant in Humansdorp. 50% of Woodlands’ milk comes from the Humansdorp and Tsitsikamma region, while the other 50% comes from the Alexandria, Cookhouse and Cradock districts.

An interesting fact is that the dairy trucks are designed to lift one set of wheels from the two sets on the back of the truck when the tanker is empty. It saves on tyre wear and tear and thus saves cost.

Woodlands Dairy is the 3rd largest dairy company in South Africa and employs 1500 people, making them the biggest employer in Humansdorp.

There’s about 1.4 million liters of milk moving through the plant daily.

Woodlands produces not just their own First Choice brand, but also packages dairy products for Spar and Woolworths. The Woodlands plant in Humansdorp produces mostly long-life (UHT) products while their sister plant, the Fairfield Dairy in KZN, produces more fresh products.

What does UHT mean? UHT milk, also known as long-life milk, is milk that has been sterilized by heating it to a very high temperature (135-150°C) for a short period, typically a few seconds, and then rapidly cooled. This process, called ultra-high-temperature (UHT) treatment, kills virtually all micro-organisms, resulting in a product that can be stored unrefrigerated for several months until opened.

Over the last few years Woodlands have gone on an all out mission to increase their various sustainability projects within the plant. With all the energy and water that they use the sustainability side of it has received priority focus and we got to see a number of the projects that they have taken on at massive costs.

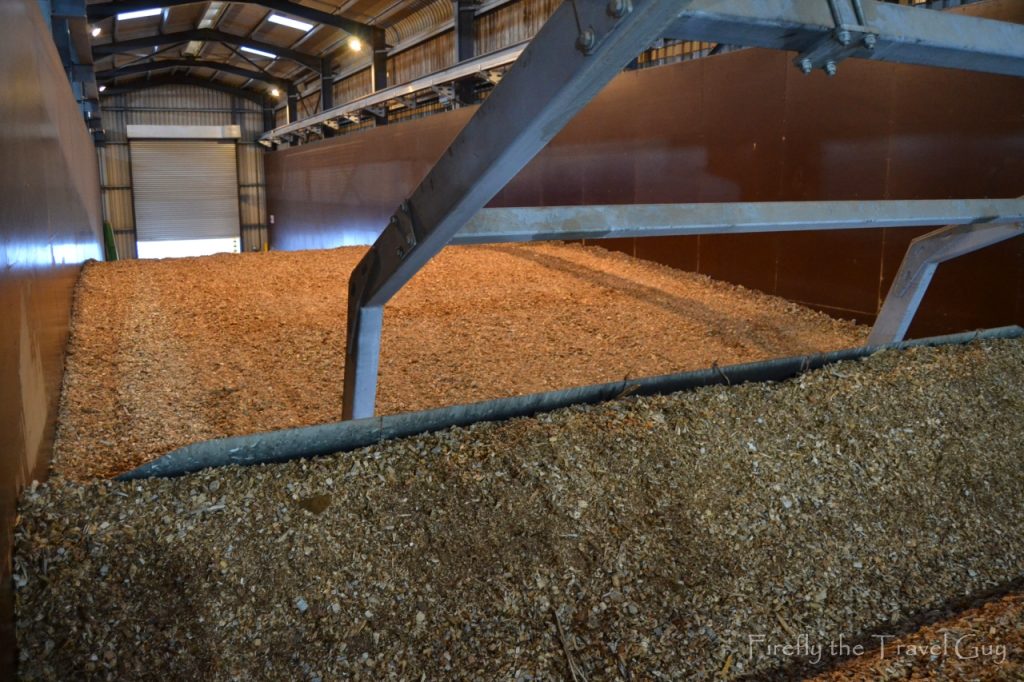

Energy management was the first we got to have a look at. In addition to acres of solar panels, Woodlands have also installed two big woodchip fired boilers to generate energy and steam.

The boilers burn woodchips that come in from the Longmore Forest sawmill near Thornhill. During busy periods they use about 125 tons of woodchips a day. That’s five 25 ton trucks a day delivering woodchips into the woodchip barn from where conveyer belts move the woodchips to the boilers.

Woodchip fired boilers are basically huge ovens. Not just a little hot to the touch. I missed the bit on everything the steam and energy is used for. Obviously, among others, to UHT the milk, but I was off elsewhere taking photos at that time.

I do know that those ovens will burn your pizza in seconds if you had to put your Hawaiian (yes, I put pineapple on pizza) into it with a paddle. In fact, the paddle will probably catch alight immediately as well.

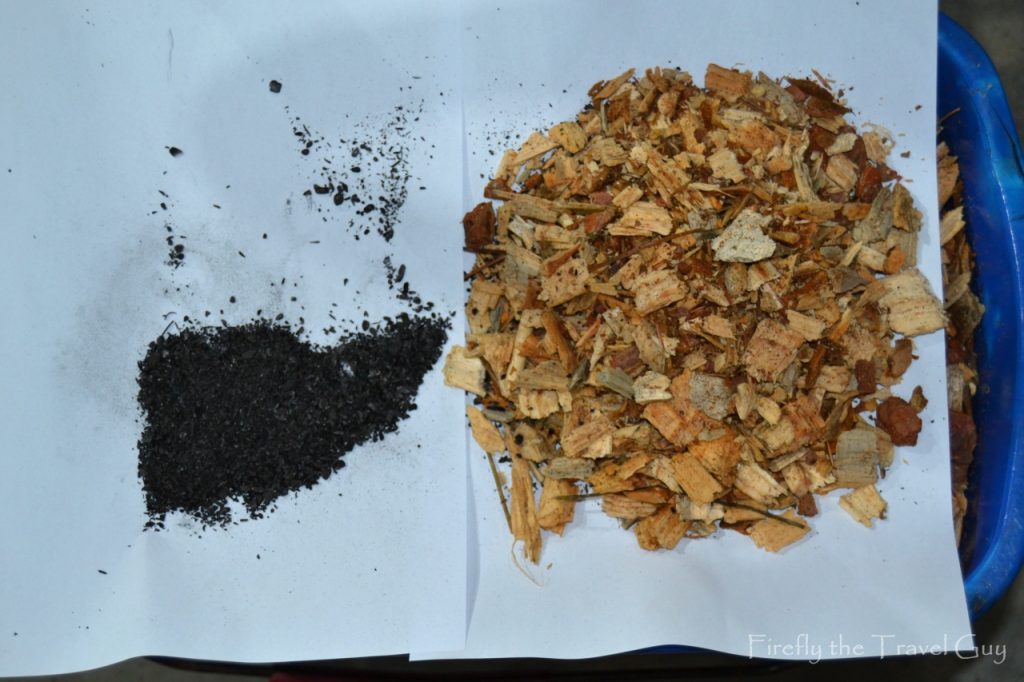

I asked them what they do with all the ash from the daily 125 tons of woodchips. The ash is fairly coarse and its sent to the farms and used as past of the compost in the camps. Don’t ask me how, just take their word for it.

I mentioned the water usage on the farms a little earlier. They use even more water in the plant. In fact, the water usage at a dairy plant is humongous. I can understand why though. All the tanks, pipes, systems, trucks and everything else needs to be washed and rinsed the whole time. The water used come from the municipal system, rainwater harvested from the roof of the plant and from boreholes on the property. All the water being used then gets moved through the Water Recovery Plant where they treat 2 million liters of water a day. The smallest of the blue tanks takes 1 million liters of water, while the biggest one, also the last one in the process, holds 5 million liters.

The process is way to complicated for me to try and explain, but this is the easy way to look at it. When the used water goes into the system, it looks like the beaker on the right. It has a milky look to it and smells like old milk. After the first part of the process, the water comes out the brown colour. At this stage it actually doesn’t smell like milk anymore. The big tank has all kinds of micro organisms in it that consumes the bad stuff in the water (I’m really no scientist) and once they are done with it it looks like beaker number three. The final process is like reverse osmosis and the final product is probably cleaner than your municipal water. In fact, it then gets put back into the municipal system.

We didn’t get to see very much of the inside of the plant, but we did get a glimpse on our walk through. Miles of stainless steel pipes carry the milk to the various production and packaging stations. We could see long-life milk being packaged down below, most of it being done electronically.

It was really interested to see the caps being put onto the boxes which then got put into sixpacks and then stacked onto pallets by robots and by hand. Woodlands Dairy uses recyclable packaging and even the plastic caps are made of sugar cane and not plastic. And no, they don’t taste sweet. I have licked one before.

So let’s try again. Where does milk come from?